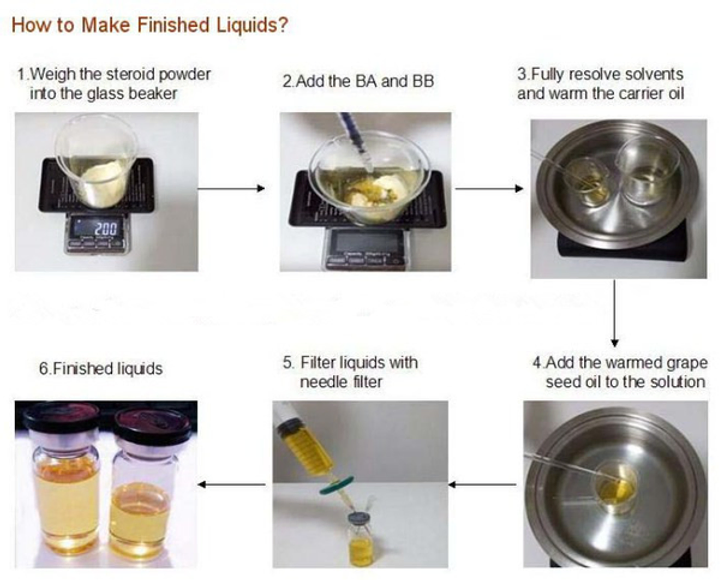

The process of making injectables from steroid powder

Carrier oil (usually grapeseed oil, a high quality oil used for injections), syringe (The syringe is used to push the unfiltered steroid mixture through the syringe filter. Choose the size of the syringe depending on how much you intend to create. The syringe can be rinsed and reused.) Benzyl Benzoate (BB), Benzyl Alcohol (BA), Sterile Glass Vial (any size), Needle, High Quality Steroid Powder, Sterile Syringe Filter .22um, Weighing (accurate to 0.01g),glass beaker.

Testosterone Enanthate 300mg/ml @ 100ml cooking recipe:

30 gram Testosterone Enanthate powder (22.5ml)

2ml BA (2%)

20ml BB (20%)

55.5ml Oil

1. weight 30g of steroid powder into a glass beaker and add 2ml BA and 20ml BB.

2. the solvent will start to dissolve the powder immediately, but to speed up the process a water bath can be used.

Place the beaker with the solvent into a pan of water a few centimeters from the bottom along with the oil (the carrier oil should be at the same temperature as the solution): it is important not to use water that is too hot as this will cause some oxidation of the product 60°C is a good temperature to use.

The goal at this point is to completely dissolve the powder into the solvent. There should be no “hormonal swirls” or any visible powder in the solution, once this is achieved, please continue to the next step.

3. Add the grapeseed oil at the same temperature to the solution, in this case 55.5 ml must be added. mix thoroughly again, there should be no hormonal swirls and move on to the filtration process.

4. remove the 0.22um sterile syringe filter from the package, secure the green needle to the smaller side, wipe the top of the sterile vial with an alcohol swab and insert the green needle and another needle next to it to equalize the internal and external pressures. Place the solution into the syringe to be filtered, this may be a single large syringe or repeated several times using smaller syringes. Apply pressure to the syringe plunger to filter the mixture.

This is the most important part of the process because it is what sterilizes the product. All finished steroids from any steroid lab must go through this process.

Sometimes, one may find that the filter is blocked or the process slows down drastically – to save time, the filter can be replaced with a new one.

Once the product is filtered into sterile vials, the process is complete.

It can also be obtained in another step.

1. 55.5 ml Oil, 2 ml BA (2%), 20 ml BB (20%) were added to a glass beaker to make a solvent. Weight 30g of steroid powder into the glass beaker.

2. Stir the solvent to start dissolving the powder immediately, but a water bath may be used to speed up the process.

Place the beaker into a pan or something similar in a few centimeters of water: it is important not to use water that is too hot as this can cause some of the product to oxidize 60°C is a good temperature. The goal at this point is to completely dissolve the powder into the solvent. Until the solution is clear, once this has been achieved, proceed to the next step.

3. Remove the 0.22um sterile syringe filter from the package, secure the green needle to the smaller side, wipe the top of the sterile vial with an alcohol swab and insert the green needle and another needle next to it to equalize the internal and external pressures. Place the solution into the syringe to be filtered, this may be a single large syringe or repeated several times using smaller syringes. Apply pressure to the syringe plunger to filter the mixture.

This is the most important part of the process because it is what sterilizes the product. All finished steroids from any steroid lab must go through this process.

Sometimes, one may find that the filter is blocked or the process slows down drastically – to save time, the filter can be replaced with a new one.

Once the product is filtered into sterile vials, the process is complete.